We create Designs, We are

sunnyever

Committed to delivering ongoing innovation, precise and efficient laser equipment solutions.

reliability across multiple industries

Awesome Designs

Committed to delivering ongoing innovation, precise and efficient laser equipment solutions.

The fastest way to grow your business with the leader in Technology

Use lasers for sustainable growth

Discover state-of-the-art turnkey laser technology tailored to your unique needs. Our solutions, at the convergence of photonics and automation, empower you to streamline your operations and achieve:

- Precision

- Time Optimization

- Minimal Waste

- Cost Savings

- Worker Safety

- Eco-Efficiency

What Lasers Can Do for You

360° Support for All of Your Machining Needs

Laser Cleaning

Laser rust removal, grease removal to restore the original texture, no damage to the substrate.Laser cleaning system

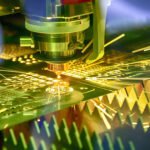

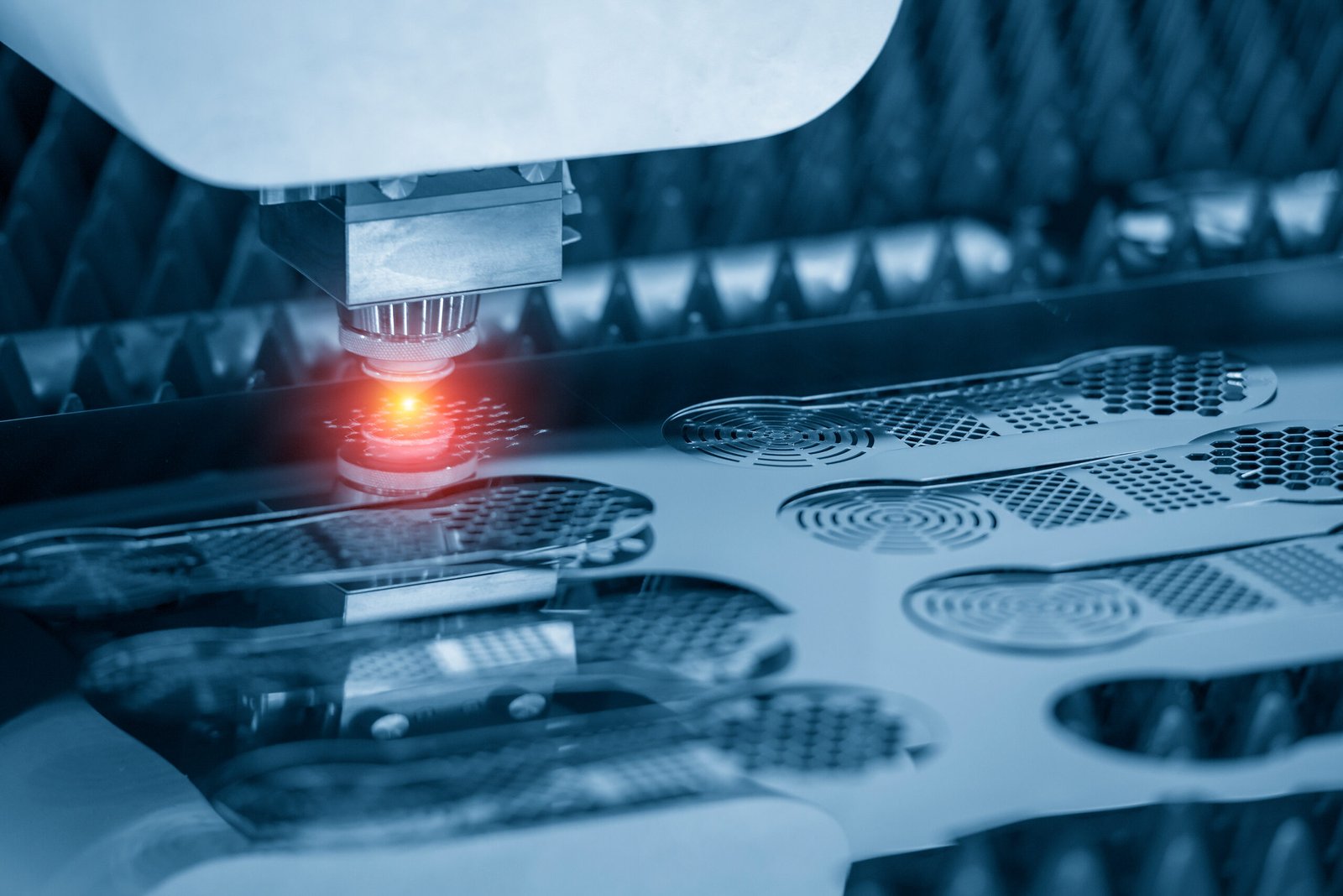

Laser Cutting

Achieve precise cuts and clean, high-quality edges.Laser cutting system

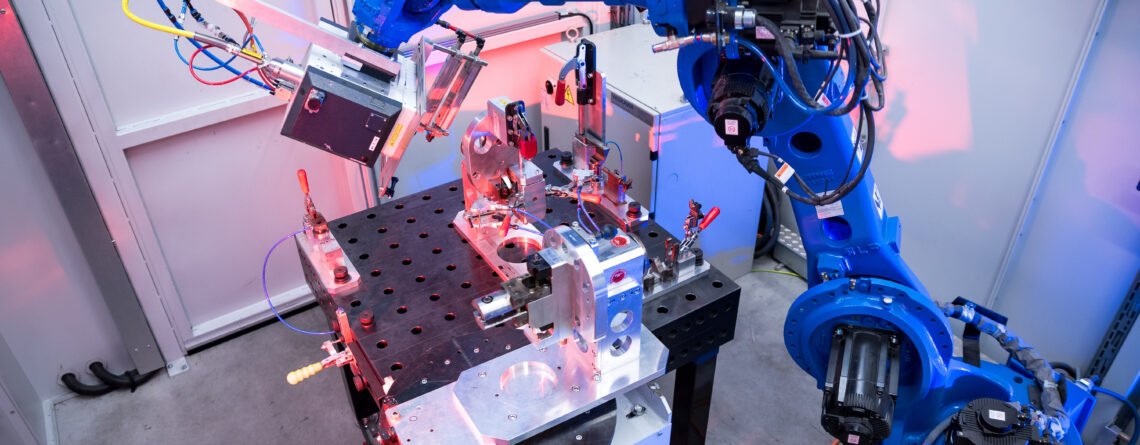

Laser Welding

Achieve strong, precise welds with minimal distortion.Laser welding system

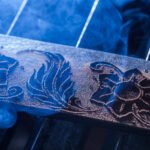

Laser Engraving

Take control of your inventory with on-the-fly component tracking.Laser engraving system

Revolutionize your cleaning process !

Adidas sports shoe mold removal case

Benefits of Laser Cleaning

Eco Friendly

Laser cleaning avoids the use of chemicals and solvents and is sustaina

Cost Effective

Long-term cost savings through reduced consumables

Non Contact

Cleans without touching the surface, preventing wear or damage.

Precision Cleaning

Precisely target surfaces, minimizing damage to delicate parts

Versatility

Removes rust and other contaminants from multiple types of substrates.

Reduced Downtime

Boosts operational efficiency and productivity

LASER CLEANING

PULSED LASER SERIES EQUIPMENT

Non-damage cleaning, EHS friendly, High efficiency, No cleaning media needed, Cleaning cost reduction up to 80%, User friendly, automation available

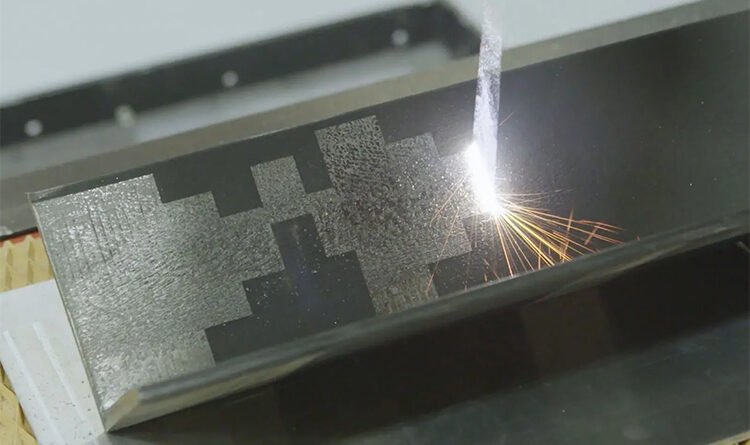

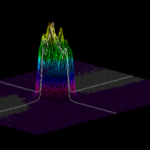

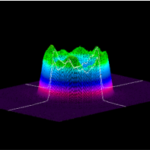

Cleaning effect of single mode multi-mode laser

The following is a comparison of the cleaning effect of single mode, multi-mode and square spot, and the square spot composite cleaning is mainly used in precision parts

Sunnyever Laser cleaning SLQX-M300S-1/ SLQX-M300S-2

Non-abrasive | Precision | Efficiency

Application range Metal rust layer treatment coating, oil, grease cleaning oxidation layer, film layer, glue layer cleaning welding or painting before treatment paint layer cleaning pipe cleaning tire mold wheel cleaning stone tablet surface dust and attachments removal

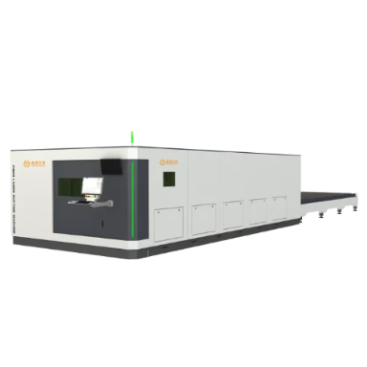

Supporting electric auto-focus adjustment, is designed for medium/high power of laser cutting. With sensor unit, controlling unit and driving unit integrated inside, it is a wonderful solution for achieving complete automatic cutting.

SUNNYEVER is precisionHigh speedextremely practical and fully responsive.

Our commitment to your results doesn’t stop after the sale. We want to ensure that you get the most out of your fiber laser machine investment. That’s why we offer best-in-class resources to put the knowledge you need within easy reach..

Our laser equipment excitedhappy caters to all your machining needs

2000 customers in 50 countries use SunnyeverLaser machine . Meet our Customers.

Is Dated Technology Holding You Back?

In today’s industrial landscape, businesses face multiple challenges that hinder their expansion and progress. Outdated tools commonly used in industrial cleaning, marking, cutting, and welding processes lead to secondary waste, material loss, workforce hazards, and environmental harm, thereby incurring substantial long-term costs.

Businesses taking a proactive approach to improving their ESG performance can now take advantage of cutting-edge laser technologies. At Laser Photonics, we recognize the importance of addressing industrial challenges head-on, which is why we offer innovative solutions that mitigate costs, minimize environmental impact, and prioritize the health and safety of your workforce.

Agile Laser Solutions Across Industries

Our equipment Portfolio

SLQX-M500S-1/2

lienraiola@gmail.com2025-01-25T08:09:53+00:00FCP F-K

lienraiola@gmail.com2025-01-25T09:18:53+00:00FCT L12-K Series

lienraiola@gmail.com2025-01-25T10:26:58+00:00SLQX-F

lienraiola@gmail.com2025-01-25T08:07:30+00:00SLQX-M100FB

lienraiola@gmail.com2024-12-17T06:30:37+00:00Welding 1

lienraiola@gmail.com2024-12-16T10:16:29+00:00- John Smith. Okler

- Sofia Johnson .

We cooperate with customers in various industries

Why should you ask Sunnyever?

Services

Innovative Technology

We leverage cutting-edge laser technology to provide advanced cleaning and welding machines. Our equipment ensures high accuracy, reduced operational costs, and minimal environmental impact, all while maintaining maximum productivity.

Reliable Performance

Sunnyever products are engineered for durability and reliability. Our machines are built to withstand the most demanding industrial environments, ensuring consistent, high-performance results with minimal maintenance.

Customizable Solutions

We understand that each industry has unique needs. Sunnyever offers a wide range of customizable options for both laser cleaning and welding machines, enabling businesses to tailor our equipment to their specific operational requirements.

User-Friendly Design

Our machines are designed with the user in mind. Intuitive interfaces, ergonomic designs, and safety features are incorporated to make our equipment easy to operate, even for complex tasks. This ensures that your team can quickly adapt and maximize productivity.

Comprehensive Support

Sunnyever provides comprehensive pre-sales consultation and after-sales technical support to ensure that every customer receives the best possible service. Our dedicated team is available to help with everything from machine setup to long-term maintenance.

Proven Track Record

With years of experience and a growing global customer base, Sunnyever has built a strong reputation for delivering dependable laser solutions. Our commitment to excellence ensures that we consistently exceed customer expectations.

Latest News

The advantages of laser cleaning of metal surfaces before welding.

lienraiola@gmail.com2025-01-26T04:42:05+00:00Laser cleaning equipment can replace traditional pre-welding and post-welding cleaning methods for...

Laser deburring improves component quality

lienraiola@gmail.com2024-12-15T05:07:20+00:00Laser deburring has been used in some large-scale production processes in the...

Laser surface treatment technology beyond laser cleaning

lienraiola@gmail.com2025-01-26T04:59:57+00:00For a long time, laser technology has been widely known for its...

Laser cleaning technology

lienraiola@gmail.com2025-01-26T04:54:36+00:00IntroductionIn recent years, laser cleaning has become one of the research hotspots...