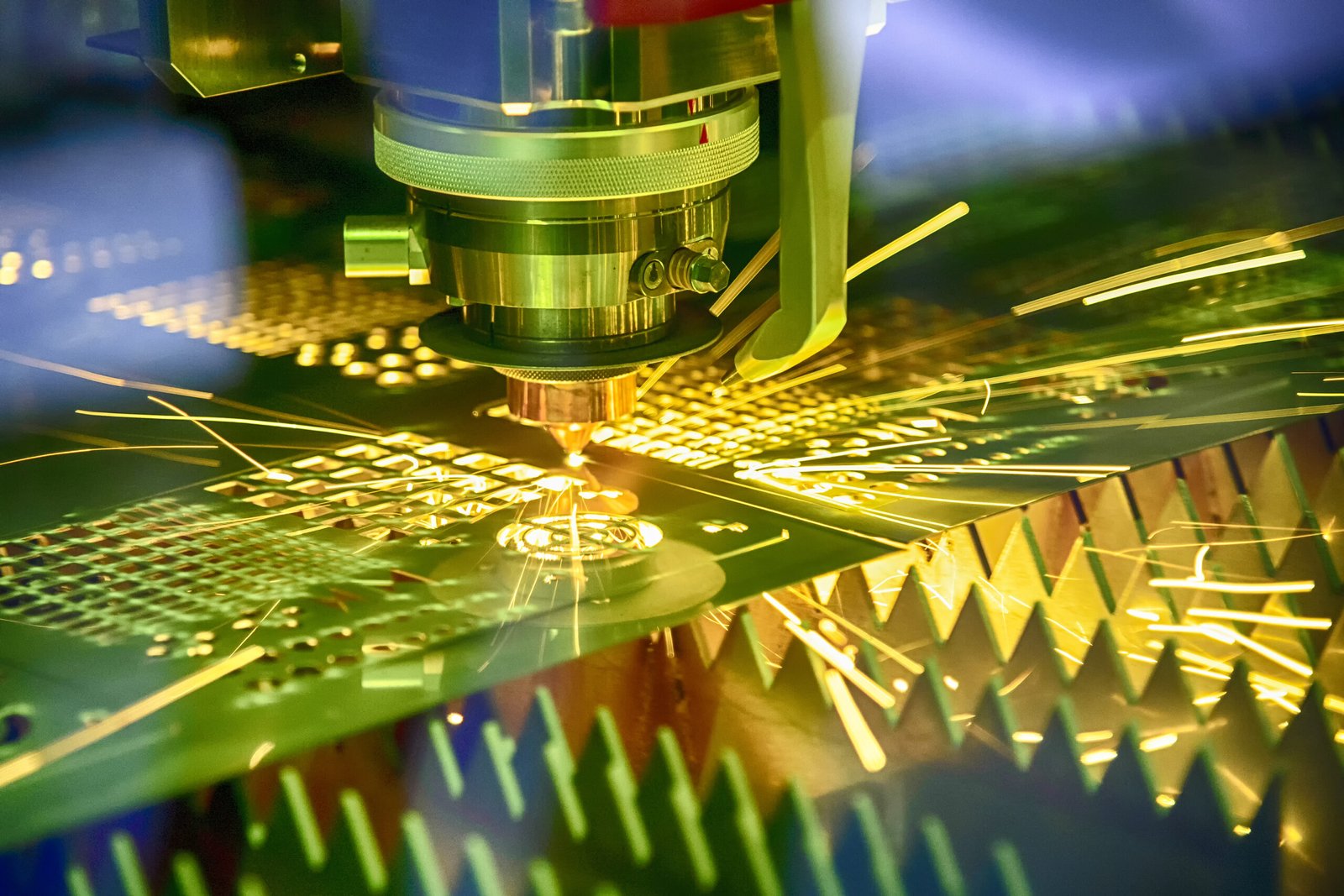

Laser deburring improves component quality

Laser deburring has been used in some large-scale production processes in the automotive industry for the past decade. But the potential of this technology has far from been fully realized, says Dr. Edgar Willenborg, an expert in laser polishing and laser deburring from the Fraunhofer Institute for Laser Technology. Especially for deburring sheet metal, it is not only simple to carry out but also improves component quality.

Many benefits

Smooth and rounded edges prevent cutting and damage to cables and surfaces. But the laser process can do more: it makes the edges defect-free. Willenborg emphasizes: This leads to clear advantages in the fatigue strength and mechanical forming properties of sheet metal parts. Tests on high-strength steel have shown that the fatigue strength is increased by 220% after laser deburring. At the same time, the degree of deformation increases by 240%. Previously, edge cracks could be avoided. Laser melting removes micro-defects at the edges caused by machining. This pre-damage, which is invisible to the naked eye, is often the starting point for crack formation.

Laser deburring is fast, clean, and inexpensive.

Another major advantage of laser deburring compared to mechanical processes is that it does not produce grinding dust.Since laser deburring only briefly melts excess material instead of removing dust, it can be integrated into existing process chains and production environments relatively easily. Where integration is feasible, the advantages quickly become apparent. He emphasizes: Laser deburring is particularly suitable for components that are subject to high stresses. Take chassis parts, for example: The increased fatigue resistance in the edge area allows manufacturers to design them thinner, which reduces weight and ultimately increases fuel efficiency.

Comments (2)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae, gravida pellentesque urna varius vitae.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae, gravida pellentesque urna varius vitae. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam viverra euismod odio, gravida pellentesque urna varius vitae. Sed dui lorem, adipiscing in adipiscing et, interdum nec metus.