What Is Laser Cutting?

Failsafe Precision Machining

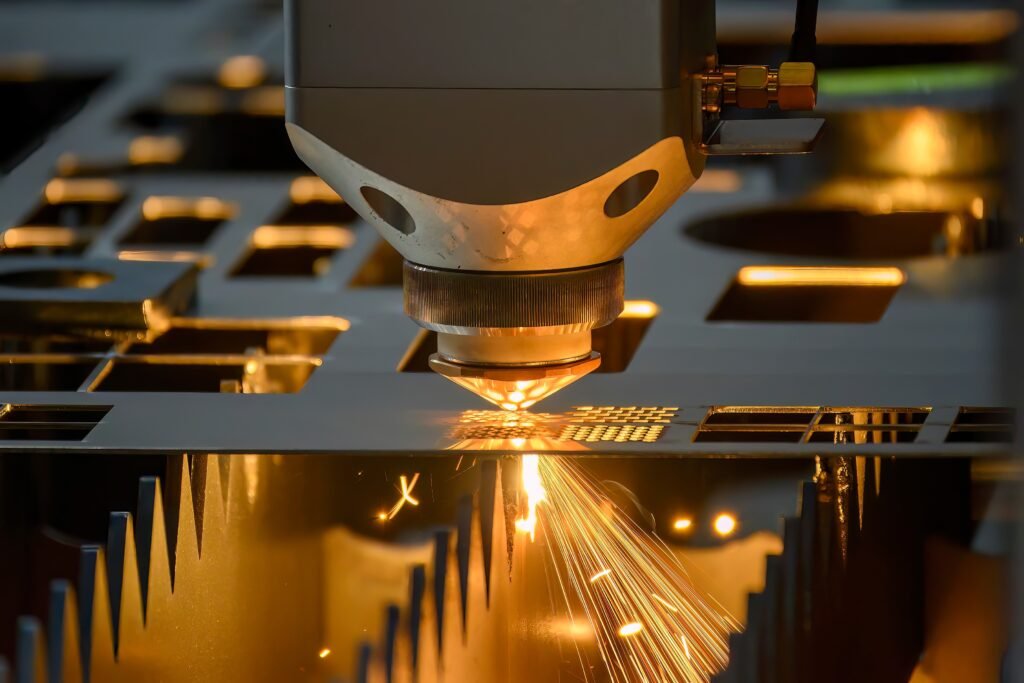

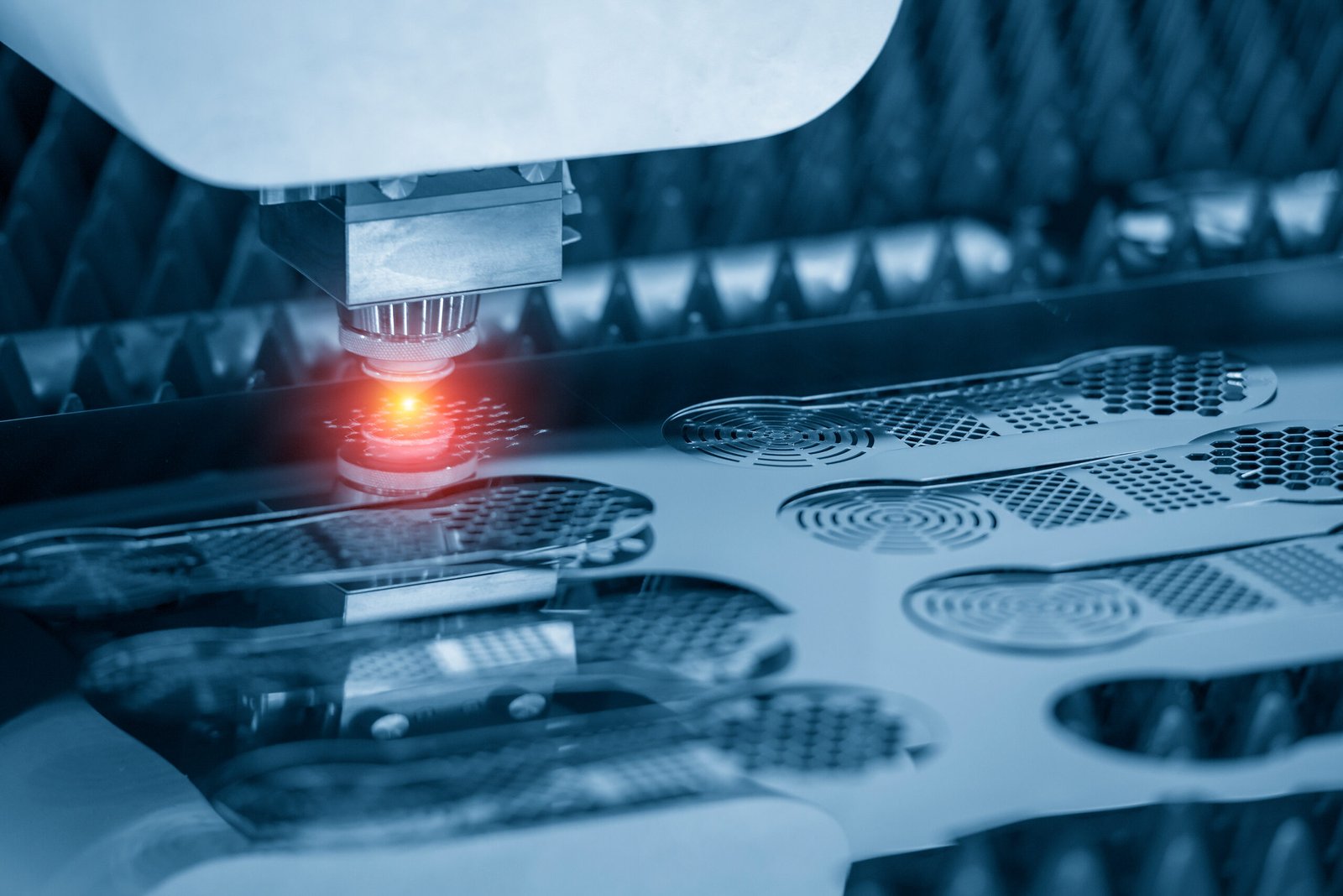

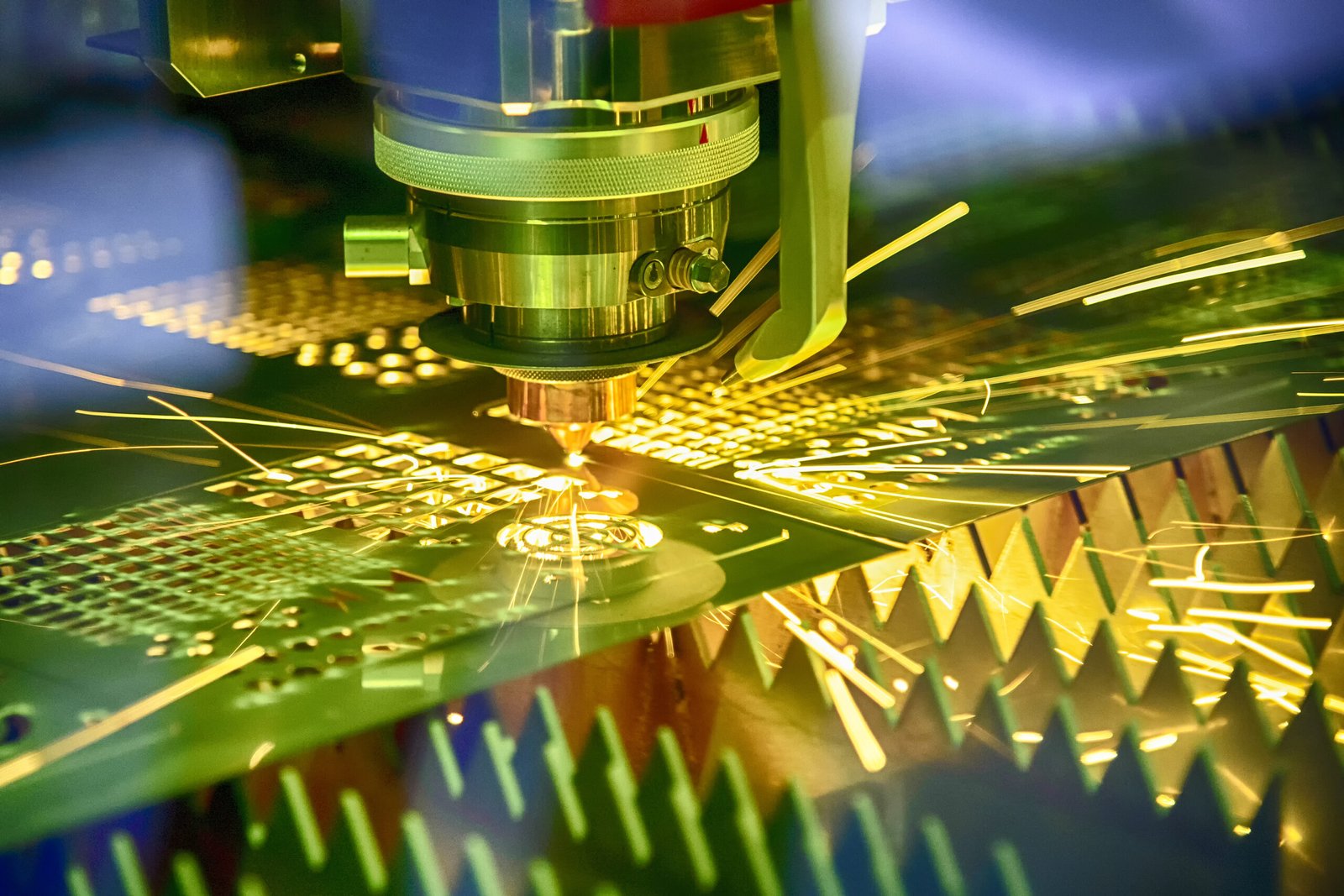

A fiber or CO2 laser cutting machine relies on the thermal impact of infrared light to cut through materials with high accuracy. This laser light is focused into an intense beam to produce a narrow cut with extremely clean edges. This non-contact, automatable technology delivers fast, highly consistent results in machining intricate geometries..

Laser Cutting vs. Other Methods

Discover how fiber laser cutting outperforms other cutting techniques in terms of precision, maintenance, and consumable use.

Long-Term Cost Savings

While the initial investment into a laser cleaning system

may be significant,integrating this technology promises long-term benefits and returns. When handled properly laser-powered tools require minimal upkeep and proyide reliable,consistent performance for years.Team Laser Photonics can help make that happen with the help of its user training and maintenance professionals

Low Heat-Affected Zone

Fiber laser cutting systems by Laser Photonics integrate

our proprietary Turbo Piercing technology, which greatlyreduces the heat-affected zone (HAZ) during cutting. A low HAZ means minimal thermal stress on the material. whichleads to less warping and preserved structural integrity This makes laser cutting tools excellent for manufacturing

parts with tight tolerances, reducing the need for extensivepost-processing.

Superior Cutting

Laser cutting systems deliver consistent, high-quality cuts

with the utmost control and precision. A non-contact

process, this method offers significant advantages in producing intricate desians with minimal kerf and less ris!of damaging the material. This transforms a task oftenassociated with costly rework and post-processing into aquicker, more efficient operation.

Long-Term Cost savings

While the initial investment into a laser cleaning system

may be significant integrating this technology promises long-term benefits and returns. When handled properly laser-powered tools require minimal upkeep and provide reliable,consistent performance for years.Team Laser Photonics can help make that happen with the help of its user training and maintenance professionals..

Laser Cutting Applications

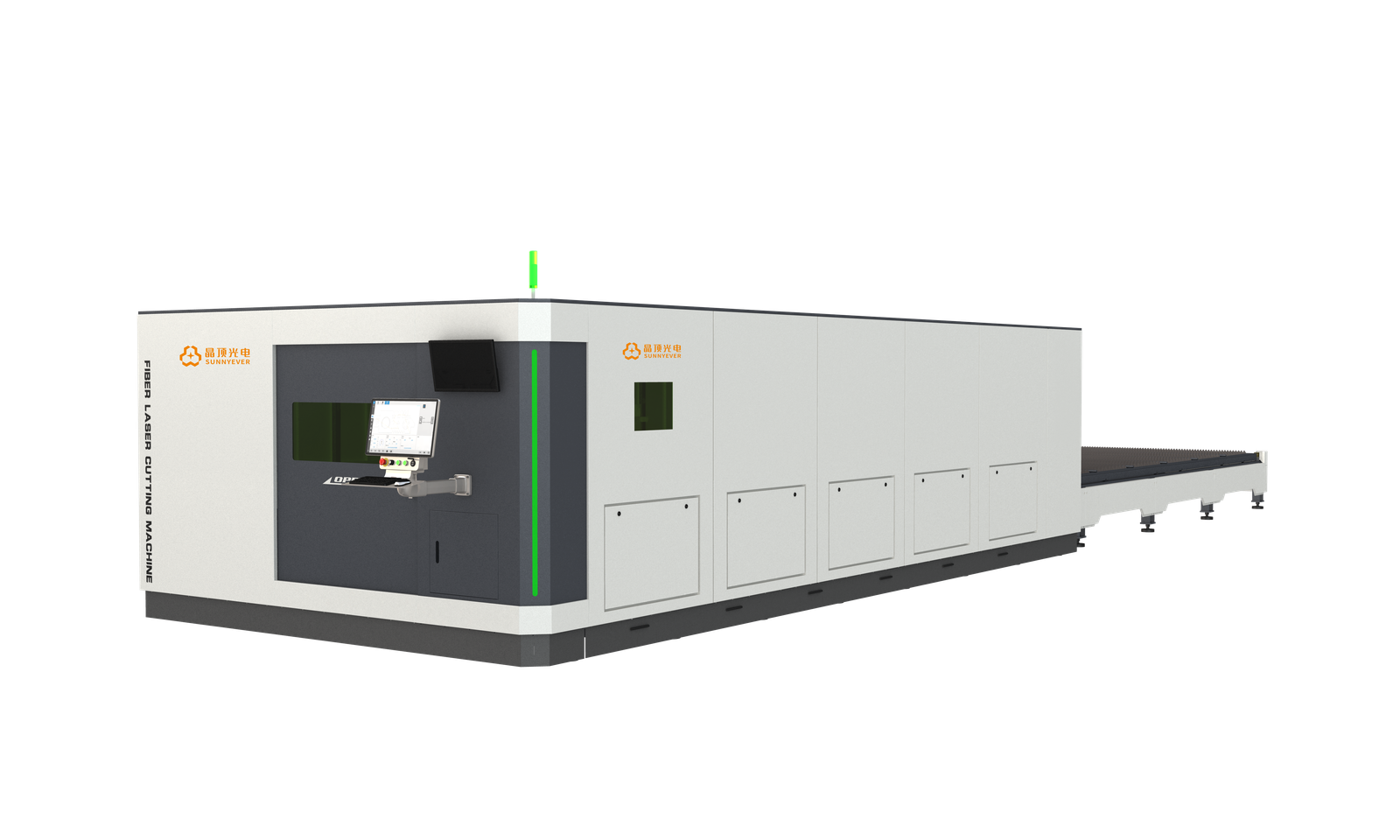

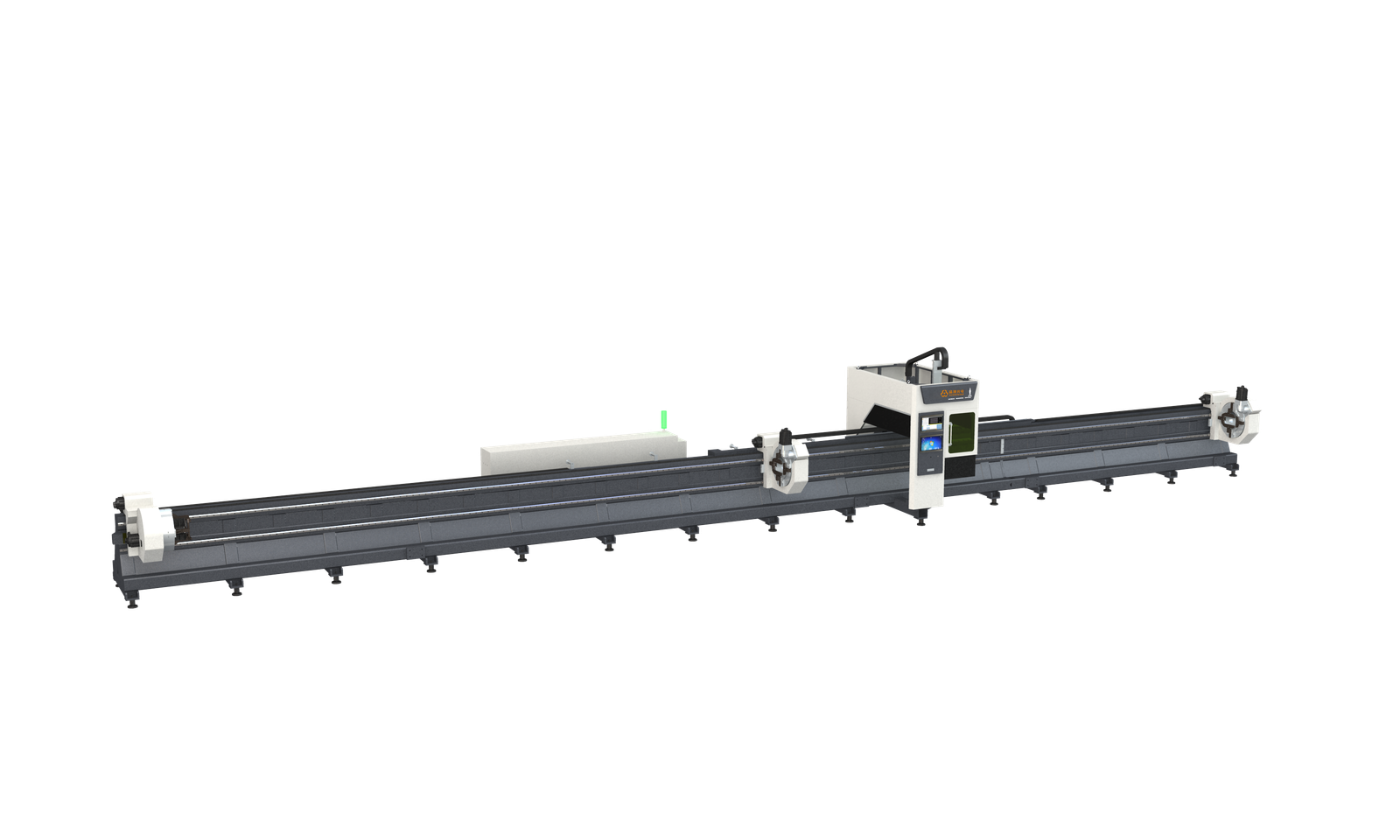

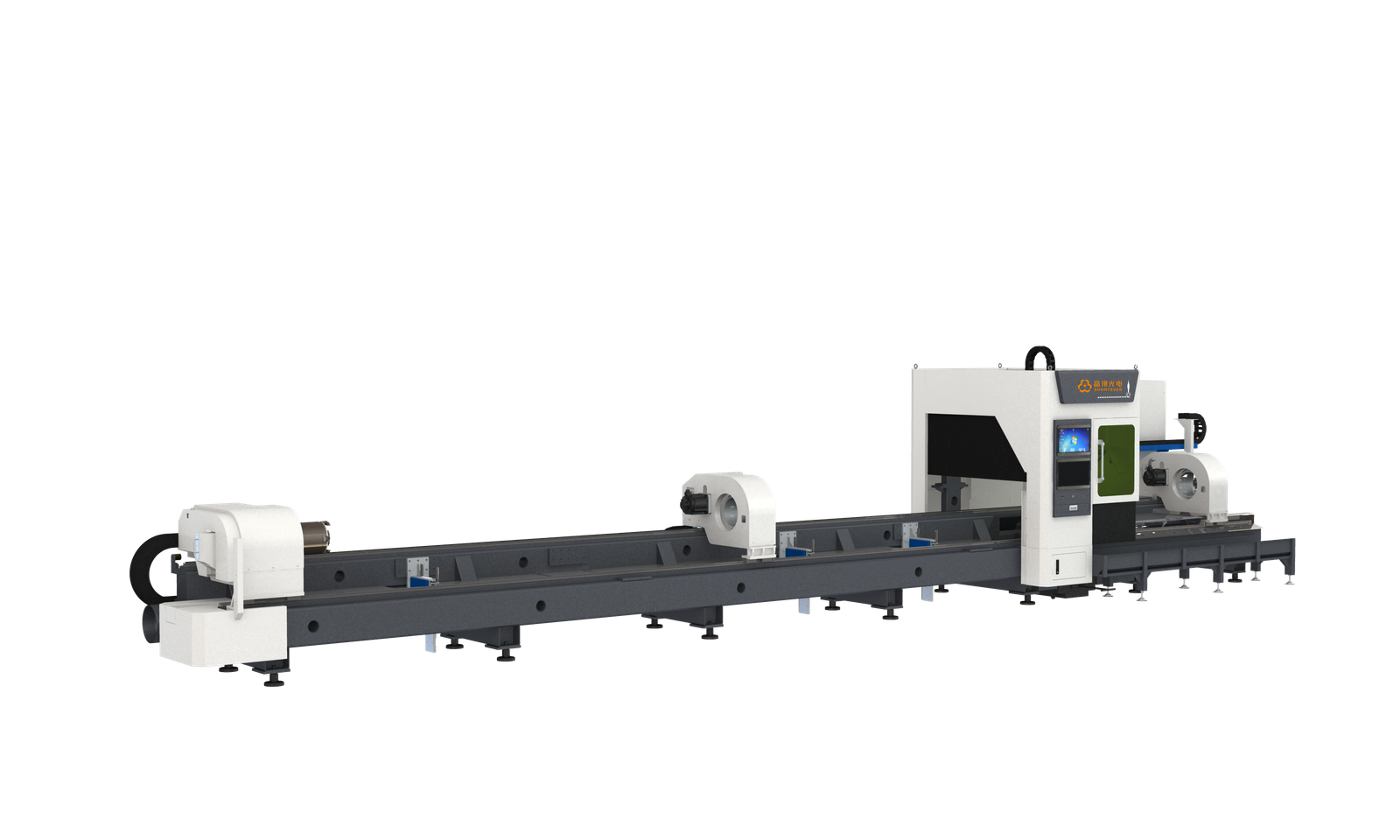

For ultimate safety during laser processing, select among the fully enclosed laser equipment by Laser Photonics. Although infrared laser light is invisible to the human eye, accidental exposure can pose the risk of eye and skin damage. With Class I laser systems, laser radiation is fully contained inside an enclosure with safe viewing windows.

Discover the Benefits of Laser Cutting

Elevate Your Maintenance, Repair, and Operations Processes With Laser Cutting

Laser Photonics offers semi-automated laser cutting systems with custom configurations. Our in-house engineering team is ready to provide you with the laser machining experience that will best suit your needs.

Mechanical Cutting vs. Laser Cutting

Unlike mechanical cutting, which involves sawing, shearing, milling, or similar power tools and carries a high margin for error, laser cutting is a contactless, CNC-controlled process. Of the two methods, laser cutting is the more precise and yields a clean edge. Laser cutting significantly reduces material waste, rework, and post-process surface finishing..

Waterjet Cutting vs. Laser Cutting

While both a waterjet cutter and a laser cutter require a considerable initial investment, the former requires considerable ongoing operational and maintenance expenses. In addition to the cost of abrasives in waterjet cutting, operations involve the upkeep of the high-pressure system, fixing any leaks or wear, and post-process cleanup. In comparison, laser cutting stands out for its quick maintenance and low consumable use..

Plasma Cutting vs. Laser Cutting

Of these two methods, laser cutting generates a lower heat-affected zone, which leads to less material distortion and damage. Plasma cutting is considered an affordable method; however, a plasma pulse does not have the precision of a laser beam and may not be suitable for cutting thin or intricate materials. In comparison, laser cutting is more versatile and safer for a variety of applications and materials. In addition, plasma cutters require regular replacements of torch consumables and gas replenishment..

Our Laser Cutting Solutions

Your Top Choice for Fast & Precise Cutting

这是标题

这是测试文本,单击 “编辑” 按钮更改此文本。